This causes the outside lite of glass to heat up more than the inside lite as the coating converts radiant heat from the Sun into sensible heat. The coating is usually applied to the "number two" surface (the inside face of the outside lite).

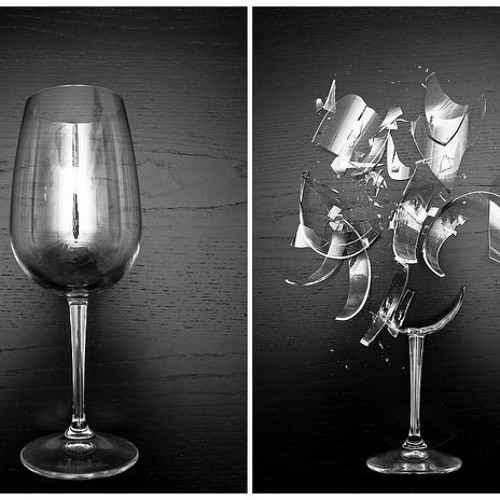

These are also known as "stones", and can also break the glass when the glass is heated, as they create thermal anomalies.īreakage due to thermal stress is most common in large pieces of sealed insulating glass with heavy heat-absorbing (reflective) coatings. This type of breakage is almost always found in tempered glass and is indicated by a distinctive "figure eight" pattern, with each "loop" of the figure eight approximately 30 mm in diameter.Īlternatively, small pieces of refractory brick can be eroded by the molten glass from the internal walls of the furnace during processing and become embedded in the finished glass. When these stresses exceed the strength of the glass, breakage results. Small shavings of stainless steel containing nickel change structure over time and grow, creating internal stresses in the glass. The most common cause of these inclusions is the use of stainless-steel machinery in the glassmaking and handling process. Nickel sulfide inclusions ("stones") can be present in the glass. Internal defects and inclusions in the glass If no space is provided at the perimeter of the unit, the glass will bind against the frame, causing internal stresses to develop in the glass which can exceed the strength of glass, resulting in breakage. The gaskets holding the glass in the frame are also usually resilient to cushion the glass against wind buffeting. Glass expands and contracts with changes in temperature and deflects due to wind, so almost all modern glass is set on resilient blocks at the bottom and with space for expansion at the sides and top. In the case of tempered glass the entire unit usually breaks.

However, over time, as the glass expands and contracts, stress concentrations can develop around the nick, leading to breakage. These small nicks or chips may not result in immediate breakage. It is also possible for fasteners such as nails or screws used to attach glass stops to nick the glass edges if these fasteners are installed at an improper angle. While glass is being moved and installed, it is easy for the glaziers to nick or chip the edges of the glass with various tools. Inadequate glass thickness to resist wind load.Binding of the glass in the frame, causing stresses to develop as the glass expands and contracts due to thermal changes or deflects due to wind.Minor damage during installation such as nicked or chipped edges later developing into larger breaks normally radiating from point of defect.Internal defects within the glass such as nickel sulfide inclusions.4 Internal defects and inclusions in the glass.

0 kommentar(er)

0 kommentar(er)